Startseite > VXC

VXC

VXC Evaporative Condenser

Compact and reliable

The VXC is a pressure principle radial counterflow condenser with a tube bundle design according to PED 97/23/EC for a capacity range from 60 to 6,920 kW (nominal R22 kW for single cell models). They therefore supply the full nominal thermal capacity for a wide range of requirements as well as for various refrigerants. VXC models are suitable for indoor installation and occupy minimal floor space. They are highly reliable throughout the year and are ideal for noise sensitive environments.

Operating principle

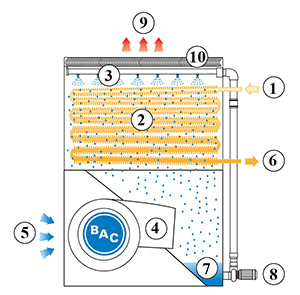

Steam (1) flows through the condenser coil (2), which is moistened with water by the spray system (3). At the same time, the radial fan (4) blows ambient air (5) from bottom to top through the evaporative condenser. During operation, heat is transferred from the tube bundle of the internal circuit to the water and then to the atmosphere, while part of the water evaporates. The liquefied steam then leaves the unit (6). The tub (7) or basin collects the water. The spray water pump (8) returns the water to the spray system. The warm saturated air (9) leaves the condenser through the droplet separators (10), which remove the water droplets from the air.

Typical applications are:

- Tight spaces and installations requiring a single air inlet

- Installation with limited floor space

- indoor installations

- Noise-critical installations

- Dry operation in winter

Main advantages of the VXC:

- Reliable

- Quiet

- Compact

Main advantages in detail

Since 1978, thousands of VXC evaporative condensers have been installed worldwide, demonstrating the reliability of this series every day. The fan, motor and drive system (V-belt) are located in dry air, protecting them from moisture and condensation. Since the VXC has no external moving parts, it can withstand the harshest weather conditions. The use of various corrosion-resistant materials, such as the unique Baltibond hybrid coating, guarantees a long service life. A finned tube coil with steel fins for dry operation is also available as an option.

VXC evaporation condensers contain quiet internal radial fans and therefore cause only minimal ambient noise. The one-sided air inlet and a quieter rear panel allow the VXC to be optimally aligned for more noise-sensitive areas. The operating noise can be further reduced by specially developed and tested silencers or water silencers.

The compact design of the VXC is ideal for enclosed spaces and the one-sided air inlet allows it to be placed next to solid walls. Radial fans enable a supply air and exhaust air duct system as they overcome the static pressure of an external duct system. Therefore, the VXC can be installed indoors.

Evaporative cooling units minimise the energy consumption of the entire system due to their lower operating temperatures and are considerably more efficient than conventional air and water-cooled condenser systems. They also reduce energy costs and at the same time protect raw materials and the environment.

The VXC is available in a wide range of sizes in finely graduated power steps. This makes it possible to select the optimum device for every system configuration and every requirement profile. The VXC series offers the widest selection of evaporative condensers in the industry and meets all installation and application requirements in practice.

VXC units are factory assembled. Larger models are supplied in two parts to reduce the size and weight of the heaviest component and allow easy on-site assembly with smaller, less expensive cranes. The one-sided air inlet requires fewer motor starters for installation and wiring. The VXC offers high performance with minimal operating weight. It can be safely mounted on a steel substructure provided by the customer and is also suitable for roof installations. The VXC-C models can be delivered in a closed standard container. To ensure that the lower fan section fits through the container doors, the fan housings are shipped loose in the water basin area and can be easily assembled on site.

The inside of the unit is easily accessible: adjusting the float valve, cleaning the sieve and rinsing the tub is therefore completely problem-free.