Startseite > HXI

Hybrid cooler | HXI

HXI - Hybrid cooling tower with closed cooling circuit

The HXI hybrid cooling tower is an axial multi-flow cooling tower for an output range up to 1,630 kW with a maximum air inlet temperature of 82°C. The HXI hybrid cooling tower is designed for a maximum air inlet temperature of 82°C. It has a closed cooling circuit and combines the advantages of evaporative coolers with those of dry cooling (sensitive cooling). The HXI provides full thermal rating for a wide range of flow rates and temperatures. Characteristic advantages of this hybrid recooler include exhaust air heating to avoid steam and considerable water savings compared to conventional evaporative coolers. Standard design features meet today’s environmental requirements, minimize installation costs, maximize reliable year-round operation and simplify maintenance.

Operating principle

Hybrid coolers can operate in three different modes to suit ambient temperatures and cooling requirements

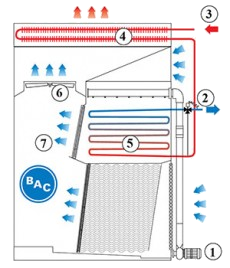

Dry operation

During dry operation, the spray water system (1) is switched off and no energy is required for the pumps. The liquid to be cooled (3) first flows through the finned coil (4) and then through the smooth coil (5). The modulating (3-way) flow control valve (2) remains fully open to ensure that both coils maintain the full amount of fluid in series to utilize the maximum heat transfer area. An axial fan (6) sucks in the ambient air (7) via the tube bundle and the heat is dissipated by the liquid in the tube bundle. In this operating mode, no water is consumed and swaths are completely eliminated. HXI cooling towers can be economically selected for dry ball switching points from 10° C to 15° C or higher, depending on the specific requirements of the project. If the unit is to be operated in dry mode for a longer period of time, it is recommended that the cold water tank be emptied, as no antifreeze or water treatment is required.

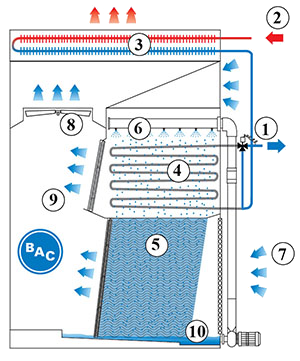

Adiabatic cooling

In adiabatic operation, the (3-way) control valve (1) allows the liquid to be cooled (2) to flow alone through the finned coil (3) and the smooth coil (4) is passed completely. A small quantity of circulating spray water (6), which moistens the smooth tube coil and the packed packing (5), serves to saturate and adiabatically precool the incoming external air (7), which is blown over the finned tube coil by an axial fan (8). Under most climatic conditions, the ambient air can still absorb a lot of moisture (9). Therefore the adiabatic cooling of the incoming air leads to significantly lower air temperatures, which in turn considerably prolongs the times of sensitive (dry) heat transfer. The remaining spray water is collected in a tank with a gradient (10) and pumped back into the spray circuit. Compared to conventional evaporative coolers, visible vapors and water consumption are significantly reduced while maintaining the low liquid design temperature required to maximize system efficiency.

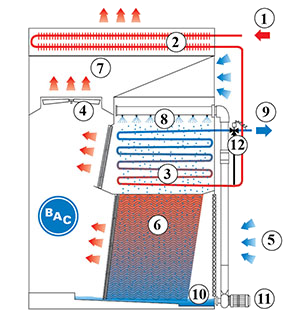

Wet/dry operation

In this mode, the liquid to be cooled (1) first flows through the dry finned coil (2) and then through the evaporative smooth coil (3) where the cooled liquid leaves the unit (9). Spray water from the cold water basin (10) is pumped into the water distribution system (8) above the smooth coil (11). The humidification of the smooth tube coil enables evaporation cooling. The spray water falls from the smooth coil over the packing (6) and improves heat transfer by cooling the spray water. Air is sucked both over the smooth coil and over the packing, where it is saturated with moisture and absorbs the heat. However, the air is still cold enough to achieve considerable cooling within the finned coil installed at the outlet above the fans (4). Both sensitive and evaporative cooling are used in wet/dry operation. Compared to conventional evaporation units, the risk of swaths is considerably reduced and even at peak loads, water can be saved considerably. At lower heat loads and/or low outside temperatures, the proportion of evaporative cooling and thus water utilisation is reduced by gradually reducing the flow through the evaporative tube bundle. This is achieved by a modulating flow control valve arrangement (12) which regulates the temperature of the outlet liquid. This control arrangement ensures maximum use of sensitive cooling in the finned coil and minimum use of evaporative cooling in the smooth coil. The heat transfer method and flow control are arranged to achieve maximum water savings in wet/dry operation.

Typical Applications are:

- Medium to large climate and commercial applications

- Water saving

- swath reduction

Main advantages of the HFL

- No swaths

- Highly efficient use of water

- Cost saving

Main advantages in detail

The HXI hybrid cooler offers the choice between evaporative cooling, adiabatic heat transfer and dry cooling. This significantly reduces the formation of swaths. In cold outside temperatures, when the risk of vapour formation is particularly high, the HXI runs in dry operation so that no vapour can form. Even in wet operation, the formation of vapours is reduced by pre-cooling the process liquid in the dry finned tube coil, the finely adjustable quantity of spray water and by heating and drying the blow-off air at the finned tube coil. In dry operation there are no vapours.

The HXI features patented flow control with a 3-way valve for precise adjustment of the liquid outlet temperature. It can be flexibly adapted to the load profile and external conditions by choosing between dry, adiabatic and wet/dry operation. Even under peak load in wet/dry operation, it consumes considerably less water than a conventional evaporation recooler because the process liquid is already pre-cooled dry. In some areas, water savings alone can pay for the device in two years.

The finned tube coil allows higher water inlet temperatures than traditional closed-circuit cooling towers because the incoming liquid is (pre)cooled dry. In this part of the process neither water consumption nor vapour formation takes place.

The energy consumption of the HXI is very low due to its highly efficient axial fans with low kW output and a motor system with several fans. In dry operation, there is no need for any energy for the pumps. The unique evaporative cooling PLUS with its combined heat transfer system saves energy system-wide. The low water consumption also lowers operating costs, and this is accompanied by lower water treatment costs. In addition, the use of a closed cooling circuit prevents impurities in the process. A simple inspection and maintenance does not only lead to a higher operational safety and a longer service life, but also saves maintenance costs.

The HXI cooling tower has a large hinged door that provides convenient access to the internal catwalk in the spacious maintenance channel so it can be maintained and inspected standing up. The patented multi-current technology reduces evaporation directly from the tube bundle, reducing the risk of deposits as the parallel flow of air and spray water virtually eliminates dry spots. The tube bundles can be inspected from the outside during operation and also from the inside via the removable droplet separator modules. The patented BACross packing steel sheets reduce fouling and allow easy inspection without disassembly. They are accessible from the inside as well as from the outside via the removable air intake protection elements. Optional BACross filling packages are available for quick cleaning and easy removal of the packing. The inclined position of the filling material and the slope of the cold water basin lead to a continuous self-cleaning by rinsing out dirt and foreign bodies. The HXI has anti-turbulence structures with a removable suction strainer. The fresh water and the overflow are easily accessible from the outside for inspection and cleaning.

The multi-blower motor system consists of an independent fan motor and one drive assembly per fan with a maintenance duct section for independent fan operation for additional performance control or as a standby fan in the event of a fan failure. The use of various corrosion-resistant materials, such as the unique Baltibond hybrid coating, guarantees a long service life of the HXI hybrid cooling towers. The one-sided air inlet and air outlet is suitable for most installation conditions. The patented heat transfer system, consisting of multi-flow technology, heat exchanger coil and packing, is ideal for applications where temperature fine tuning is required as well as thermal challenges. The patented intelligent flow control ensures that the outlet temperature remains constant and that the energy and water consumption is as low as possible.

The easy cleaning and inspection of the HXI reduces the hygiene risks due to bacteria and biofilm inside the HXI. The combined air inlet protection elements block sunlight and thus prevent biological growth in the tower. They also filter the air and ensure that no water splashes outside. The patented BACross filler reduces fouling and Eurovent certified droplet separators prevent droplets from getting into the air.