Startseite > HFL

Hybrid cooler | HFL

HFL - Hybrid cooling tower with closed cooling circuit

The HFL is a radial countercurrent Hybirdkühler for a performance range up to 1,275 with a maximum liquid inlet temperature of 82°C. The HFL hybrid recooler combines the advantages of dry and evaporation-based cooling. The possibility of choosing between three different operating modes allows the user to select the mode in which the appliance with the lowest energy and water consumption provides the cooling capacity required.

Operating principle

The HFL has three different operating modes so that the unit can be optimally adapted to the cooling requirements and the ambient temperature.

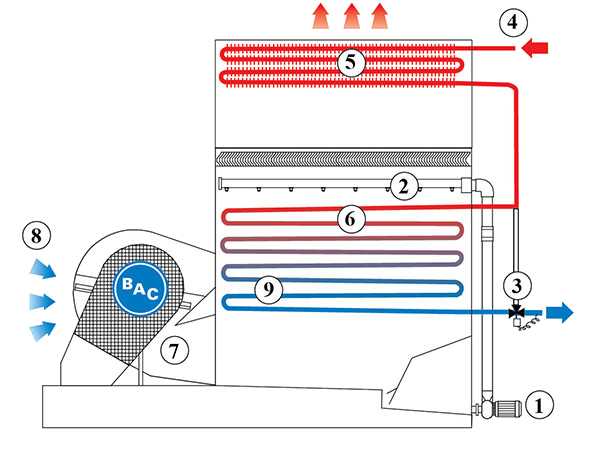

Dry operation

The spray water pump (1) and the spray system (2) are switched off and the modulating (3-way) control valve (3) is fully open. The warm process liquid (4) flows through both the finned coil (5) and the smooth coil (6). A fan (7) blows the ambient air (8) over the tube bundle and cools the liquid (9) in the tube bundle. In this mode no water is consumed and no swaths can form.

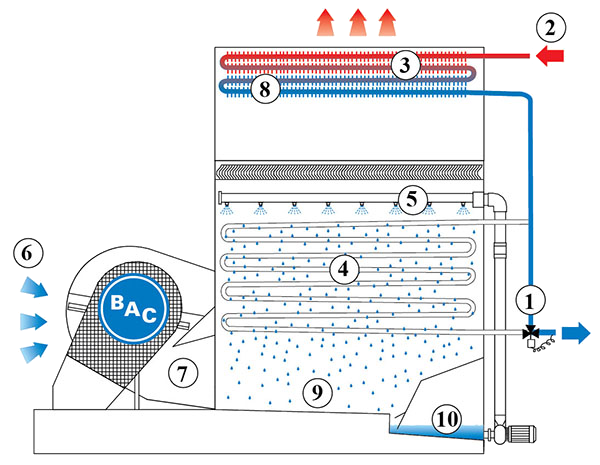

Adiabatic cooling

The (3-way) control valve (1) allows the hot process liquid (2) to flow only through the finned coil on the discharge side (3), passing through the wet smooth coil (4). The smooth coil is moistened by the spray water (5), but there is no evaporation of water for the purpose of heat dissipation. However, part of the water evaporates and humidifies the incoming ambient air (6), which is blown over the tube bundles by a fan (7). This saturated air has a better cooling capacity to cool the process liquid (8) in the finned tube coil. The spray water falls into a maintenance channel with an inclined bottom (9) and is emptied into a separate wet tub (10). The pump lets the water flow back to the spray system. Visible vapour and water consumption are significantly reduced, while the design temperature at the liquid outlet is maintained.

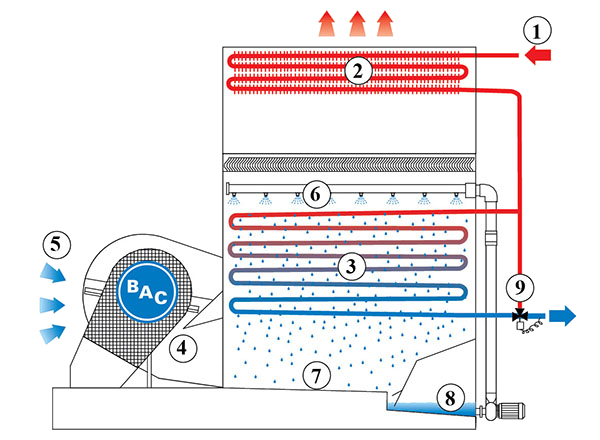

Wet/dry operation

The warm process liquid (1) flows both through the finned coil (2) and through the smooth coil (3). A fan (4) blows the air (5) over the tube bundles. At the top, where the warm liquid enters the tower, the exhaust air is saturated and pre-cools the liquid. Then another heat transfer process takes place in the smooth coil, which is moistened by the spray system (6). The spray water falls into a maintenance channel with an inclined bottom (7) and is emptied into a separate wet tub (8). The pump lets the water flow back to the spray system. When the heat load is lower or the ambient temperature drops, the modulating valve (9) controls the flow through the smooth coil so that the design temperature at the liquid outlet is maintained. This also minimises vapour formation as there is less evaporated water and the exhaust air is heated with the dry finned coil.

Typical Applications are:

- Medium to large climate and commercial applications

- Limited space and height and installations requiring a single air inlet

- indoor installations

- Noise-critical installations

- Environments where vapour formation must be avoided

Main advantages of the HFL

- Minimal water consumption

- Light and compact

- Excellent hygiene control

Main advantages in detail

The HFL allows water savings of up to 60% compared to a conventional evaporative cooler. This is achieved by making optimum use of the heat exchangers in this hybrid cooling tower. The coolant is first fed to the finned coils and then to the smooth coil, which can be operated in either wet or dry mode. The finned coils also contribute to heat dissipation in summer when the smooth coil is operated wet. Since the installation of the finned coil has significantly increased the heat exchanger surface area, the HFL can work not only in winter, but also in spring and autumn and, depending on the load profile, in dry operation for most of the summer season. To further improve the water saving function of the hybrid cooling tower, an optional flow control with a three-way valve can be integrated into the pipeline between the finned and smooth coil, allowing precise adjustment of the liquid outlet temperature. This intelligent control system ensures that evaporative cooling only takes place when required.

The HFL hybrid cooling tower has an extremely compact design. The low models have up to three fans, which are driven on a common shaft with an electric motor. Double cells can be arranged next to each other without any gaps, so that the available space can be used to the maximum. The arrangement next to each other is possible because access to the wet tub is at the rear end (connection end) of the unit and access to the dry tub is only sufficient from one side. Since the tank capacity of the HFL is only a quarter of that of a conventional evaporative cooler, its operating weight is very low. The water-saving recoolers contain only the amount of water required for humidifying the smooth coils. This avoids having to construct the support for all the load created by the amount of water in the tub but which does not contribute to the cooling process. The HFL therefore fits perfectly into tight spaces and on roofs.

Depending on the cooling requirements and weather conditions, the HFL can be operated dry for approx. 10 months a year. Access to the compact wet tub, which is insulated from the dry tub by a partition wall, is via rectangular access doors at the connection ends of the units. This makes the wet tub accessible, even when the fan system is in operation. This is not possible with conventional devices with printing principle configuration. The fresh water can be checked and the tub sieves can be cleaned while the recooler is in operation. Due to the partition wall, there is also no turbulence in the bath water, which is caused by the air flow in conventional construction. The maintenance points in the dry pan access have round access doors on the side of the unit. The drying tank has a gradient so that all the water sprayed over the pipe coil (during wet operation) drains into the wet tank. The wet tub is compact and can be easily emptied and cleaned. Disinfection of the wet tub is also possible without any problems, should this be necessary.

The finned coils installed in the exhaust air flow of the HFL increase the temperature and reduce the relative humidity of the exhaust air. During wet operation, the formation of visible vapours is thus not suppressed, even if the relative humidity of the air is high. The installation of the optional flow control with three-way valve further reduces vapour formation, as it optimises the use of evaporative cooling as required under all atmospheric conditions. Therefore, the air leaving the “wet” part of the unit is drier than with conventional evaporative coolers and has less tendency to generate vapour. The combination of a finned coil on the discharge side and flow control with three-way valve virtually eliminates the formation of visible swaths even in extremely humid conditions. During dry operation there is no vapour formation.

The HFL is equipped with low-noise radial fans. The one-sided air inlet allows the quieter rear side of the tower to be directed towards noise-sensitive areas.

The one-sided air inlet allows the HFL to be placed next to solid walls. The units can be installed indoors thanks to the radial fans that enable the supply air and exhaust air duct systems. The low operating weight simplifies installation on site.

Hybrid cooling towers can only be optimally used if it is possible to switch from dry operation to wet operation and vice versa without any problems at any time. If water remains in the tub during dry operation, there is a risk of ice formation and subsequent damage at temperatures below freezing point. For this reason, other manufacturers recommend emptying the tub during dry operation. However, depending on the climatic conditions, this may not be possible, as emptying or refilling the tub takes several hours and cannot be carried out in a 24-hour cycle. Therefore, the installation of a conventional intermediate tank in a heated building area is recommended, which leads to additional complexity, costs and space requirements. The HFL hybrid cooling tower has a unique tub design consisting of a wet and a dry tub. During dry operation, all the water flows from the drying tank into the wet tank, which is shielded from the air flow. The heaters in the wet tub prevent freezing at temperatures as low as -25° C, even when the fans are operating at maximum speed. Both tubs are integrated into the unit, providing for the first time complete flexibility of operation with the safety of a tundish arrangement in a factory assembled product. The use of various corrosion-resistant materials such as Baltibond hybrid coating guarantees a long service life of the devices.