Startseite > ice storage > TSU-C/D External melt

Ice storage | TSU-C/D & TSC

TSU-C/D and TSC: External melt

The TSU-C/D is an ice accumulator with an external melting system for direct refrigerant or glycol injection with a capacity range from 325 to 5,060 kWh.

Operating principle

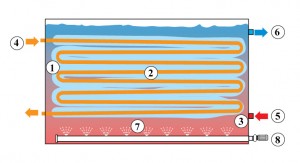

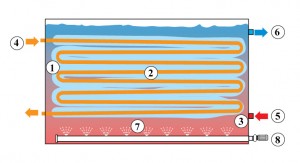

The TSU-C/D is an external melting system that produces and builds ice (1) around a tube bundle (2) immersed in water (3). A refrigerant or cold glycol (4) flows through it as ice accumulates on the outside. The ice is melted by circulating warm water (5) from the load above the tube bundle, causing the water to cool (6). Low pressure air (7) is distributed under the tube bundle by an air pump (8) for water movement.

Typical Applications are:

- food processing

- breweries

- dairies

Main advantages:

- Reliability: constant water supply temperature (1 to 2° C)

- Low investment costs

- energy conservation

Main advantages in detail

Refrigeration systems with an ice reservoir provide a constant water supply temperature of 1 to 2°C. In addition, the ice storage also buffers possible failures of refrigerating machines and thus ensures greater system availability. This also makes it possible to carry out maintenance work on the chillers during the day.

Since the refrigeration system is designed on the basis of average requirements and not peak loads, the overall system can be dimensioned much smaller. This is not only reflected in the costs for the individual system components (cooling machines, pumps, piping), but also in the operating costs (maintenance, refrigerant, etc.).

Energy savings result primarily from the smaller dimensioning of the overall system. In addition, the ice build-up at night not only saves energy costs, because electricity is cheaper at night, but also because the lower outside temperatures at night mean that less energy is consumed.

The TSU-C/D operates in two main operating modes or cycles. A possible combination of these operating cycles provides the flexibility to meet the daily climate or cooling requirements. However, long periods of simultaneously circulating glycol or ammonia through the pipes and circulation of water through the ice reservoir should be avoided to optimize system performance.

In this operating cycle, ice is formed by circulating ammonia or a 30% solution (by weight) of ethylene/propylene glycol with inhibitors through the tube bundles installed in the ice storage device. At the beginning of the ice formation cycle the temperature is higher, while at the end of the ice formation cycle the temperatures are lower.

In this operating cycle, the warm return water is cooled by direct contact between the water and the ice, melting the ice stored in the modular ice storage device.

TSC: User-specific tube bundles

The ice storage pipe bundles consist of smooth steel pipe coils with a continuous outer diameter of 26.7 mm. They are mounted in a steel frame that supports the weight of the coils during full ice build-up. After production, the tube bundles are tested for leaks with compressed air at a pressure of 13 bar under water and then hot-dip galvanized for corrosion protection. The coils are arranged to allow counterflow glycol flow in adjacent circuits for maximum storage capacity.

Single tube bundles can be factory-made into modules of two tube bundles to optimize transportation costs and reduce on-site assembly time. The glycol distributors are coated in the factory with a cold-galvanized surface. Necessary profiles and lifting eyes are attached to the tube bundles to allow lifting to the final position in the storage tank. You can also integrate these tube bundles into your existing ice storage systems.

Operating principle

The TSC tube bundle is intended for use in an external melting system. This system produces and builds ice (1) around a tube bundle (2) immersed in water (3). A refrigerant or cold glycol (4) flows through it as ice accumulates on the outside. The ice is melted by circulating warm water (5) from the load above the tube bundle, causing the water to cool (6). Low pressure air (7) is distributed under the tube bundle by an air pump (8) for water movement.

The basic ice storage system contains an ice storage device, a refrigerating machine and an ice water pump. The unit consists of several pipe bundles installed in an insulated water tank. Both the tube bundle and the tank are made of hot-dip galvanized steel for corrosion protection. If there is no cooling load, the chiller runs to build up ice on the outer surface of the tube bundle. This ice build-up is achieved by feeding coolant directly into the tube bundle. To increase heat exchange during the ice building cycle, the water is moved by air bubbles from a low pressure distribution system under the tube bundle. When the ice has reached the design thickness, the exclusive ice thickness control sends a signal to turn off the chiller. When cooled water is required for cooling, the ice water pump is started and the melting cycle begins. Warm water that flows back from the cooling load circulates through the tank and is cooled by direct contact with the melting ice. During this cycle, the tank water is also moved to improve heat exchange and provides a constant water supply temperature of 1°C or less.