Startseite > CXV-D

Evaporative condenser | CXV-D

CXV-D Evaporative Condenser: Highly Efficient and Quiet in Operation

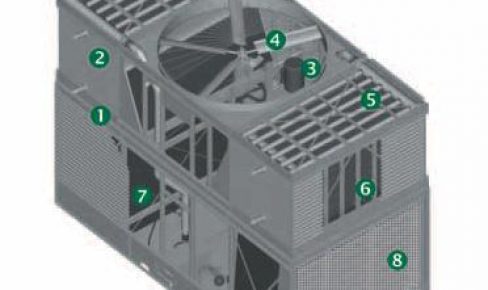

The CXV-D is an axial multiflow condenser with a tube bundle design according to PED/97/23/EC using the induced draft principle for a power range from 2,750 to 4,025 kW (for single cell models nominally R717 kW). CXV-D evaporative condensers are an extension of the CXV series for very large industrial cooling applications or process projects that require low power consumption and low noise levels. They provide full rated thermal capacity for a wide range of heat dissipation and temperature requirements for different refrigerants. Standard design features meet today’s environmental requirements by minimizing refrigerant charge and energy consumption. The devices are characterised by low installation costs, allow reliable year-round operation and require little maintenance.

operating principle

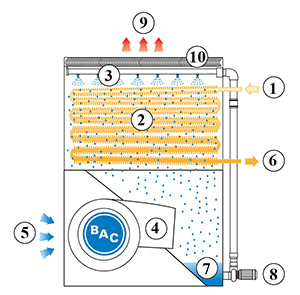

The CXV-D combines the use of evaporative condenser tube bundles with integrated packed packages for cooling the circulating spray water.

The steam (1) flows on both sides of the unit through a condenser coil (2) which is moistened by a spray system (3). Parallel to the water spray flow, axial fans (4) suck off air (5) via the tube bundles. The evaporative cooling converts the vapour into liquid (6). The spray water falls onto packing packs (7), where it is cooled before it falls into the water basins (8) or the inclined tubs. The spray water pumps (9) allow the cooled water to flow back to the top of the unit. The warm saturated air (10) leaves the tower via the droplet separators (11).

Typical applications are:

- Very large industrial cooling and process projects

- Low energy consumption

- Low noise level

Main advantages of the CXV-D:

- Highest energy efficiency

- Low maintenance and easy inspection

- Guaranteed optimum performance

Main advantages in detail

The CXV-D has evaporative cooling PLUS, a combined heat transfer system that minimizes the energy consumption of the entire system. Its high-efficiency, low kW axial fans consume half the energy of competing products and offer superior single-cell performance, further reducing energy consumption. The BACross II packing is factory configured for excellent water/air contact and minimum air side pressure drop. This guarantees optimum condenser efficiency and control of cooling system energy. The motor system with several fans, independent, highly efficient fan motors and drive assembly per fan, enables finely graduated power control.

Hinged doors provide convenient access to the interior of the unit, which is optionally supplied with an internal catwalk. Inspection and maintenance can be carried out safely and comfortably while standing. In the spacious interior, the cold water basin, droplet separator, fan drive system and condenser tube bundles are easily accessible. The parallel flow of air and water spray over the tube bundle allows inspection and access to the top of the tube bundle during operation. The internal packing and the tube bundle can be easily inspected as droplet separator modules are removable. The BACross II filler is telescopically supported for easy inspection and cleaning sheet steel by sheet steel and does not need to be dismantled. The fans are easily accessible from inside and outside. The slope of the cold water basin and the inclined position of the filling material above the basin lead to continuous self-cleaning by rinsing out dirt and foreign bodies.

The unique and patented multi-current heat transfer system is ideal for applications with temperature fine tuning and thermal challenges. The single cell performance of the CXV-D is superior to all competing products. The BACross II packing consists of a patented steel plate and guarantees maximum air/water contact for optimum heat transfer performance. The CXV-D has a long service life, as the device is coated with corrosion-resistant glass-fibre polyester.

Multi-flow technology delivers maximum performance with lowest refrigerant charge compared to all units in this performance class because the CXV-D’s tube bundle surface area is smaller. The low refrigerant charge reduces installation and operating costs and can help meet refrigerant charge thresholds.

CXV-D condensers operate ultra quietly due to the low-noise axial fans. With whisper-quiet fans, the noise level of the device can be reduced even further. Specially developed and dimensioned silencers are available to reduce operating noise at the air intake. The BACross II filler directs the water quietly and without any spray noise to the pool.

The easy cleaning and inspection of the CXV-D evaporative condenser reduces the hygiene risks due to bacteria or biofilm inside. The combined air inlet protection elements block sunlight, prevent biological growth in the tower, filter the air and ensure that no water splashes out. The droplet separators prevent droplets from entering the air. Your performance is certified and tested by Eurovent.

CXV-D Evaporative Condensers are factory assembled and supplied in parts on larger models to reduce size and weight and allow easy on-site assembly of parts with a smaller, cost-effective crane. The few pipe bundle connections reduce costs for pipes, valves, vents and manpower.