Startseite > S3000E

Open cooler | S3000E

Open cooling systems - S3000E

The open cross-flow cooling tower S300E with axial fans has a performance range of 18 – 285 l/s with a maximum water inlet temperature of 55°C (standard tower packing) to 60°C (alternative tower packing). The water is distributed by gravity with weir dams for variable flow control. Low energy consumption and low maintenance requirements ensure economical operation. The S3000E has been tested and certified by Eurovent.

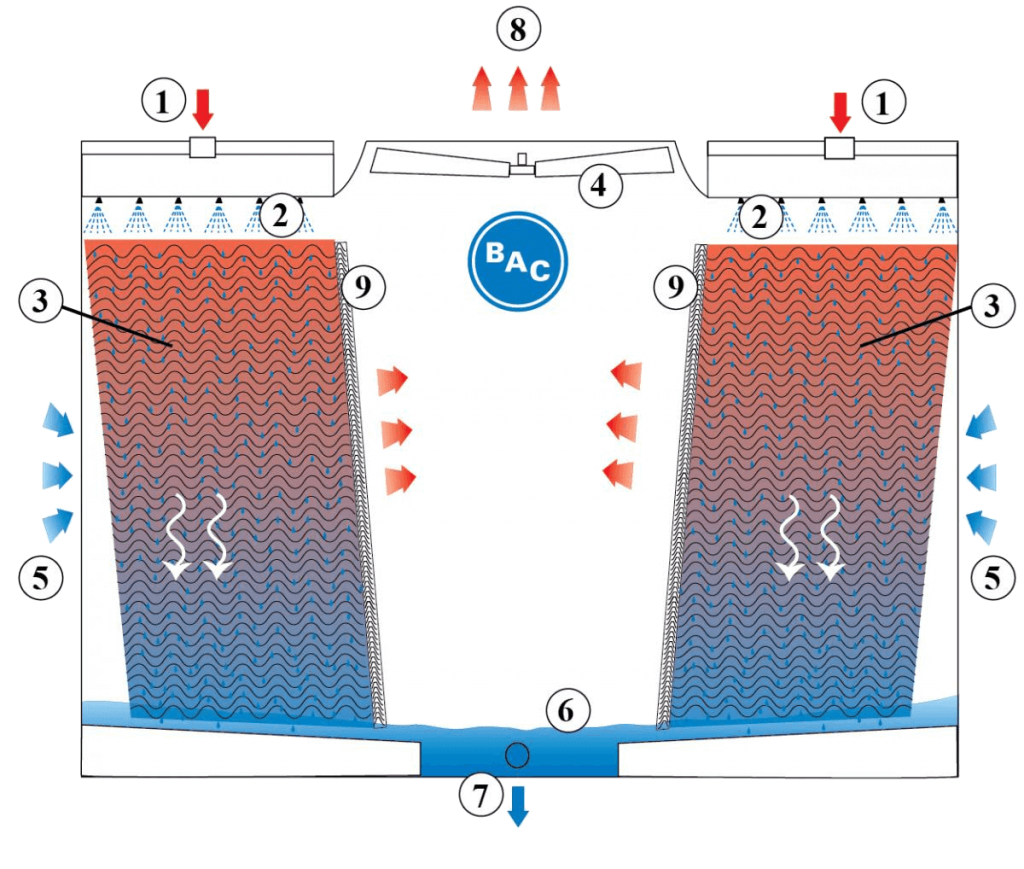

Operating principle

Hot process water (1) flows from the top of the cooling tower on both sides into the water distribution (2). There it is distributed via the packing or the heat transfer medium (3). At the same time, the axial fan (4) located at the top of the unit blows air (5) from the sides of the unit over the packing. When the hot process water meets the cold air, the latter is heated and part of the process water evaporates, removing heat from the rest of the water. The trough (6) or inclined basin collects the cooled water, which then returns to the heat source of the process (7). The warm saturated air (8) first passes the droplet separators (9), which remove the water droplets from the air, and then leaves the tower at the top.

Typical applications are:

- Medium to large climate and industrial applications

- Exchange of locally erected towers

Main advantages of the S3000E:

- Extremely low noise level, extremely powerful counterflow units with axial fans

- Unprecedented energy savings, payback period of less than 2 years

- Low maintenance and easy inspection, 25% reduction in annual maintenance costs

Main advantages in detail

For the S3000E a selection of different low-noise and whisper-quiet axial fans is available for minimum ambient noise. The BACross fillers direct the water quietly and without water splashing noises to the pool. In addition, silencers developed, tested and dimensioned at the factory are offered to further minimize operating noise at the air intake. The XES3000E series with smaller, quieter motors is suitable for extremely noise-sensitive environments.

Evaporative coolers save energy system-wide at lower operating temperatures. Axial fans consume only half the energy of similar fan units and have highly efficient fan motors. The low pump head for this gravity water distribution system reduces the energy consumption of the pumps as well as the possibility to partially close the hot water pool with wedge dams during periods of reduced load. To optimize cooling tower efficiency, BACross fillers are designed for maximum water/air contact with low air pressure losses. By using the XES3000E series with smaller motors, power consumption can be further reduced with the same cooling capacity.

The S3000E has a large hinged door, a spacious maintenance channel and an internal catwalk, providing convenient access for safe inspection and maintenance of components inside the unit while standing. In addition, it can be equipped with a ladder and a platform for quick and secure access. No basin needs to be drained to inspect the inside of the device or the packing package. The core of the BACross packing can be easily inspected and cleaned sheet by sheet without disassembly. Telescopic carriers for easy blade replacement are available as an option. Eurovent certified droplet separators are integrated in the packing. An inspection of the water distribution (hot water basin and nozzles) is possible during operation from outside the unit. The S3000E has anti-turbulence features with a removable suction strainer. The fans are easily accessible from inside and outside. Corrosion-resistant materials, such as the unique Baltibond hybrid coating, guarantee a long service life.

The easy cleaning of the S3000E towers reduces hygiene risks due to bacteria (e.g. Legionella) or biofilm inside the device. Inclined fillers and the slope of the cold water basin promote self-cleaning, as dirt and foreign bodies are simply rinsed out. The BACross design reduces possible fouling. Optional covers on the water distribution tray prevent foreign bodies from accumulating in the unit and an optional cleaning opening facilitates the removal of silt and sludge from the cooling tower basin. In addition, the unit can be equipped with a tub suction system to prevent sediments from accumulating in the cold water basin. Eurovent certified droplet separators are integrated in the packing. Combined air inlet-protection elements block sunlight and prevent biological growth in the tower, filter the air and prevent water from splashing out.

The S3000E cooling towers have excellent thermal performance and meet all flow and temperature requirements. Their thermal performance has been certified by Eurovent. The patented BACross packing with maximum air/water contact time offers unbeatable heat transfer performance. Corrosion-resistant materials such as the unique Baltibond hybrid coating and the GKF enclosure walls guarantee a long service life. Optionally, the S3000E cooling towers can be equipped with a drive system for more efficiency and less maintenance.