Startseite > Hybrid HXC

Hybrid condenser | HXC

HXC hybrid condenser

The HXC is an axial multi-current hybrid condenser based on the induced draft principle for a performance range from 545 to 1,895 kW with a maximum liquid inlet temperature of 82°C. HXC condensers consume significantly less water than traditional evaporative condensers because they can be used in three different modes (wet-dry hybrid cooling) to match ambient temperatures. Thanks to the standard design features, the HXC also meets additional environmental requirements by minimizing energy consumption and refrigerant charge, as well as eliminating steam. The HXC reduces operating costs, provides reliable year-round operation and simplifies maintenance.

Operating principle

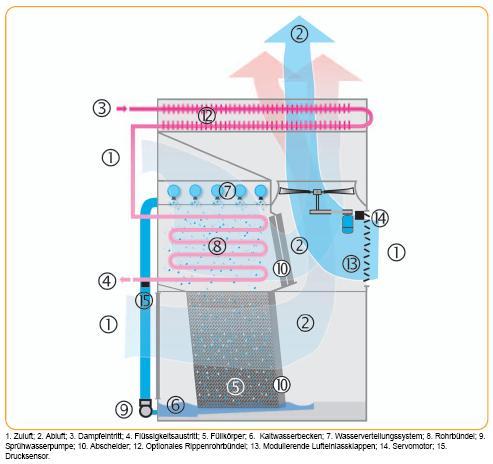

The HXC has three different operating modes that allow the system to operate optimally according to cooling requirements and ambient temperatures.

Operation with closed dampers

The steam (1) first flows through the dry finned coil (2) and then into the smooth coil (3), which is moistened by a spray system (4). When the flaps (5) are closed, an axial fan (6) draws in air via the smooth coil parallel to the water spray flow. The evaporative cooling converts the vapour into liquid (7). The spray water falls onto a packing (8), where it is cooled before it collects in the water basin (9) or the inclined tub. The spray water pump (10) returns the cooled water to the spray system. The moist heat (11) leaves the tower through the droplet separators (12) via the dry finned coil, where it additionally absorbs sensitive heat.

Operation with closed dampers

If the ambient temperature is below the condensing temperature, the dampers modulate and open. The air volume increases and the air distribution changes, so that less air is sucked in via the smooth coil and the packing. This improves sensitive heat transfer and further reduces water consumption.

Dry operation

Complete dry operation is possible when the spray pump is switched off.

Typical applications of the HXC are:

- Industrial cooling applications

- Water saving

- swath reduction

Main advantages of the HXC:

- Maximum water saving

- No swaths

- Lower refrigerant charge

Main advantages in detail

The HXC enables water savings throughout the year thanks to the various operating modes adapted to the ambient temperatures: In hot summer times the HXC is used as an evaporative condenser. But even in the “dry/wet” mode, a considerable amount of heat is removed by sensitive heat transfer, resulting in lower water consumption compared to conventional evaporative cooling. When the heat load and/or ambient temperature drops, the condensing pressure is reduced to a set point to save energy and water. If the outside temperature is low enough, flaps at the rear of the condenser open, allowing more colder ambient air to enter and improving heat transfer to the dry tube bundle, reducing water consumption. In winter a complete dry operation is possible. Lower water consumption also means lower water treatment costs. In some areas, the savings in water costs can pay for the device in just two years.

The combination of sensitive, adiabatic and evaporative cooling reduces vapour formation. In winter, when the danger of visible swaths is greatest, the HXC is operated dry and the formation of swaths is excluded. Even during wet operation, there are no swaths, as the dry finned coils reduce the humidity of the exhaust air from the smooth coil.

The smaller tube bundle surface due to the patented combined heat transfer system means less refrigerant charge and lower overall system costs. The low refrigerant requirement of the HXC reduces installation costs and can help meet threshold values. Multi-flow technology allows maximum performance with the lowest possible refrigerant charge compared to any other refrigerant condenser available.

Hinged doors and a standard internal catwalk provide easy access to the interior of the unit for inspection and maintenance while standing. In the spacious interior the cold water basin, the droplet separators, the fan drive system, the smooth pipe coil and the modulating fan flaps are easily accessible. No basin needs to be drained for internal inspection. The parallel flow of air and spray water allows access to the spray system and inspection of the top of the tube bundle during operation. The tube bundles can be easily inspected during operation due to the droplet separator modules which can be removed from the inside and outside. The combined air inlet protection elements, which can be removed from the inside and outside, make inspection of the packing uncomplicated. The patented Bacross packing steel sheets reduce fouling and allow effortless inspection of the packing without disassembly. Optional BACross filling packages are available for quick and easy removal and cleaning of the packing. The slope of the cold water basin and the inclined position of the filling material lead to a continuous self-cleaning process by rinsing out dirt and foreign bodies. The HXC has anti-turbulence structures with a removable suction strainer. Fresh water and overflow for inspection and cleaning are easily accessible from the outside.

Evaporative cooling PLUS is a unique combined heat transfer system and granulates minimal system-wide energy consumption. The highly efficient axial fans with low kW output consume only half as much energy as competitor products and have excellent single-cell performance. The drive with variable frequency or two-stage motors allows precise adaptation to the load requirement. This makes the HXC ideal for applications with temperature fine tuning and thermal challenges.

The belt drive system is made of corrosion-resistant material and uses state-of-the-art technology to ensure trouble-free maintenance and reliable performance throughout the year. The air inlet protection elements block the sunlight, prevent biological growth in the tower, filter out impurities and foreign bodies present in the air and prevent water from splashing out. The use of various corrosion-resistant materials, such as the unique Baltibond hybrid coating, guarantees a long service life.

All models can be mounted directly on parallel I-profiles provided by the customer. The units are factory installed and adjusted, complete with motors and drive. The modular design allows the equipment to be supplied in three parts to minimise the size and weight of the heaviest part to be lifted and to allow the use of smaller, lower cost cranes. A smooth coil reduces costs for pipes, valves, vents and manpower. The one-sided air inlet and outlet is suitable for most installation conditions.

The easy cleaning and inspection of HXC equipment reduces hygiene risks due to bacteria or biofilm inside. The combined air inlet protection elements block the sunlight, prevent biological growth in the tower, filter the air and ensure that no water splashes to the outside. The patented BACross filler reduces fouling and Eurovent certified droplet separators prevent droplets from entering the air. The patented multi-current technology reduces evaporation directly from the tube bundle and minimizes the risk of deposits. The parallel flow of air and spray water also eliminates dry spots that promote deposition.