Startseite > FXVE

Evaporative cooler | FXVE

FXVE

The FXVE is an axial multi-flow cooling tower based on the induced draught principle for a power range up to 1,790 kW and a maximum liquid inlet temperature of 82°C. The FXVE is designed for a maximum of 1,790 kW. The water is distributed under pressure. FXVE closed loop cooling towers provide full thermal performance for a wide range of flow and temperature requirements. They meet today’s environmental requirements, minimize installation costs, maximize reliable year-round operation and simplify maintenance requirements.

Operating principle

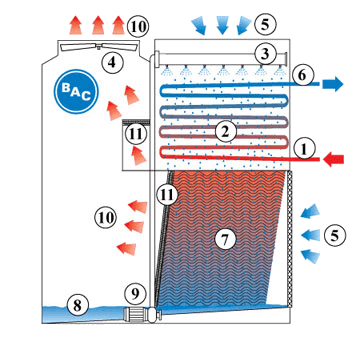

The FXVE combines the function of a cooling tower with that of a heat exchanger. The warm process liquid (1) flows through a heat exchanger tube bundle (2) which is moistened by a spray system (3). Parallel to the water spray flow, an axial fan (4) sucks in air (5) via the tube bundles. The evaporation process cools the liquid (6) in the tube bundle. The process liquid flows from bottom to top in the tube bundle, as the coldest spray water and air are at the top of the tower. The spray water falls onto a packing (7) where it is cooled before falling into the water basin (8). The spray water pump (9) lets the cooled water flow back to the top of the tower. The warm saturated air (10) leaves the tower through the droplet separators (11), which remove the water droplets from the air.

Typical applications of the FXVE are:

- Small to medium climate and industrial applications such as water source heat pump circuits and air compressor cooling

- Tight spaces and installations requiring a single air inlet

- Ideal for exchanging devices

Main advantages of the FXVE

- Highest energy efficiency

- Low maintenance and easy inspection

- Unprecedented hygiene control

Main advantages in detail

The Evaporative Cooling PLUS with a patented multi-stream design minimizes the energy consumption of the entire system due to its combined heat transfer system and low operating temperatures. The FXVE delivers heat output with maximum energy efficiency thanks to its low kW axial fans and a motor system with multiple fans (independent fan motor and drive assembly per fan), enabling finer, demand-driven gradation of power control. The BACross II packing is factory configured for unprecedented water/air contact and minimal air side pressure drop. This reduces operating costs, conserves raw materials and reduces environmental influences. The FXVE models guarantee the highest cooling tower efficiency.

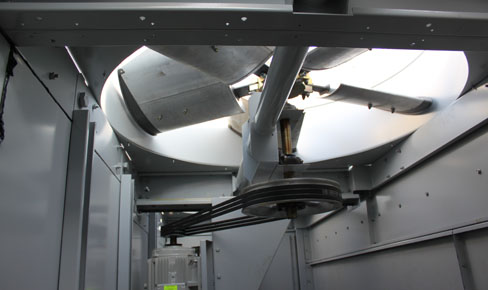

The closed cooling circuit of the FXVE reduces impurities in the system. The use of the patented multi-flow technology and the parallel flow of air and water prevents dry spots and thus reduces deposits on the tube bundle. Large hinged access doors allow easy access to the interior of the unit. All FXVE models come standard with an internal catwalk. The spacious maintenance duct provides convenient access to the cold water basin, droplet separators, fan drive system and heat exchanger coil. No basin needs to be drained for internal inspection. An optional cleaning opening facilitates the removal of sludge from the cooling tower basins. The fillers can be easily controlled from the inside and outside via removable air intake protective elements. The patented Bacross II packing steel sheets reduce fouling and are telescopically supported, allowing complete inspection of the packing without disassembly. The inclined position of the filling material and the slope of the basin lead to continuous self-cleaning. The fans are also easily accessible from inside and outside. The tube bundles can also be inspected during operation from the outside or from the inside via removable droplet separator modules. The FXVE has anti-turbulence structures with a removable suction strainer. An optional platform with safety railing facilitates external inspection: the water distribution system (spray arms and nozzles) and the top of the tube bundle can be inspected during operation due to parallel air and water flow.

The easy to clean and inspect FXVE cooling towers minimize hygiene risks due to bacteria (e.g. Legionella) or biofilm inside. The patented Bacross II packing steel sheets reduce fouling and are telescopically supported, allowing complete inspection and cleaning of the packing without disassembly. The air inlet protection elements block the sunlight and thus prevent biological growth in the tower, filter the impurities out of the air and ensure that no water splashes to the outside. Highly efficient droplet separators prevent droplets from entering the air. Your performance is certified and tested by Eurovent. An optional cleaning opening facilitates the removal of sludge and sludge from the cooling tower basin and an optional tub suction prevents the accumulation of sediments in the cold water basin.

The belt drive system uses corrosion-resistant materials and state-of-the-art technology to ensure trouble-free maintenance and reliable performance throughout the year. The unique, patented multi-stream heat transfer system uses both heat exchanger coil and packing for applications with temperature fine tuning and thermal challenges. Motor system and multiple fans ensure independent operation of fan motor and drive assembly per fan for additional power regulation or as standby fan in the event of fan failure. Corrosion-resistant materials, such as the unique Baltibond hybrid coating, guarantee a long service life.

FXVE units contain low-noise axial fans for minimum ambient noise. To further reduce noise, you should choose a whisper-quiet fan. Specially developed, tested and dimensioned silencers are available to further reduce operating noise at the air intake. The one-sided air inlet makes it possible to align the quieter rear side of the tower to more noise-sensitive areas. The BACross II fillers direct the water silently to the pool.

The multi-current design is ideal for applications that require a narrow cooling limit distance and/or large range. Models with one air inlet are designed for direct mounting on existing steel girders of both cross-flow and counter-flow devices. FXVE models offer the highest single cell performance of any closed loop evaporative cooling tower in the industry. Projects benefit from fewer cells required, lower overall fan kW and fewer pipe connections. The one-sided air inlet and outlet is suitable for most installation conditions. FXVE cooling towers are factory assembled and supplied in parts on larger models to reduce overall size and weight and allow easy assembly of parts on site with a smaller, less expensive crane.