Startseite > PCE

Evaporative condenser | PCE

PCE evaporative condenser

The PCE is an axial counterflow condenser with a tube bundle design according to PED 97/12/EC using the induced draft principle for a power range from 540 to 2,710 kW (for single-cell models nominally R717 kW).

Operating principle

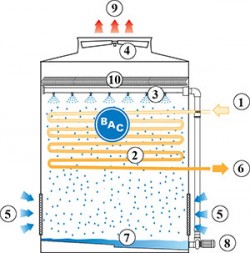

The steam (1) flows through a condenser coil (2), which is humidified by a spray system (3). An axial fan (4) sucks in air (5) via the tube bundle. The evaporation process converts the vapour into liquid (6). The spray water falls into the water basin (7) or into the tub with gradient. The water spray pump (8) returns the water to the top of the unit. The warm saturated air (9) leaves the evaporative condenser through the droplet separators (10), which remove the water droplets from the air.

Typical applications are:

- Industrial cooling applications

- Dry operation in winter

Main advantages of the PCE:

- Low energy consumption

- Low noise

- Easy to maintain

Main advantages in detail

Evaporative coolers reduce energy consumption system-wide due to lower operating temperatures. The PCE features economical axial fans that consume half as much energy as comparable radial fan units, as well as a highly efficient tube bundle and highly efficient fan motors.

The PCE is equipped with low-noise axial fans. Whisper-quiet fans can further reduce operating noise. In addition, specially developed and dimensioned silencers are available to reduce the noise level at the air intake. With water silencers, the noise level is reduced to such an extent that it almost corresponds to that of a cross-flow tower. Water silencers are always supplied with whisper-quiet fans.

The PCE is easier to maintain than other countercurrent evaporation condensers based on the induced draft principle. With BranchLok water distribution, each arm is removable for easy cleaning. The combined air inlet protection elements can be removed without any tools. The motor adjustment elements are accessible from the outside and have an integrated spanner for easy motor alignment and belt tensioning. The cold water pool is fully accessible when the combined air inlet protection elements are removed. The fans are easily accessible via a sliding door. An optional cleaning opening facilitates the removal of silt and sludge from the tank. The anti-turbulence buildings have a removable suction sieve.

Impurities present in the air cannot penetrate into the closed cooling circuit and lead to fouling of the system. Easy cleaning and inspection of PCE evaporative condenser reduces hygiene risks due to bacteria or biofilm inside. The slope of the cold water basin and the inclined position of the filling material lead to continuous self-cleaning by rinsing out dirt and foreign bodies. The combined air inlet protection elements block the sunlight, prevent biological growth in the tower, filter the air and ensure that no water splashes to the outside.

The leak-free InterLok system means the PCE evaporative condenser can be quickly installed on site. The basin in the upper part can be installed without sealing tape in between. The compact footprint is perfect for enclosed spaces. Container delivery is often possible.