Startseite > DFCV

Dry cooler | DFCV

DFCV: dry cooler with a closed circuit

The DFCV is an axial countercurrent dry cooler based on the induced draft principle for a power range from 220 to 1,500 kW with a maximum liquid inlet temperature of 60 °C. The DFCV is designed to be used as an axial countercurrent dry cooler. It is characterised by extremely simple installation and robust construction.

operating principle

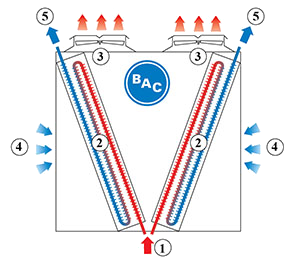

The DFCV is a V-shaped dry cooler that cools the warm process liquid (1) that flows through a finned coil (2). Axial fans (3) draw in air (4) via the tube bundle and cool the process liquid in the tube bundle (5).

Typical applications are:

- Small to medium climate and industrial applications

- Sites with limited water and space availability

- Commercial applications with high temperatures

Main advantages of the DFCV:

- Problem-free delivery and installation

- Easy maintenance

- Guaranteed thermal performance

way of working

The DFCV is a V-shaped dry cooler. The warm process liquid flows through a finned coil. Axial fans suck in air, which flows over the tube bundle and cools the process liquid.

Optionally, the thermal performance can be increased by precooler bleeding pads. For more information, see the description of the DFCV-AD.

Main advantages in detail

The DFCV is supplied compactly and completely assembled at the factory. That’s why it only takes a few minutes to set it up.

Since the DFCV is a pure dry cooler, no water treatment is necessary and a Legionella risk is excluded. Access to the dry finned coils is possible without any problems.

The thermal performance and noise level of the DFCV comply with Eurovent standards.