Startseite > CXVE

CXVE - Evaporative Condenser

CXVE evaporative condenser: highly efficient and reliable in operation

The CXVE is an axial multiflow induced draft condenser with a tube bundle design according to PED/97/23/EC for a power range from 440 to 2,765 kW (single-cell models nominal R17 kW). It supplies the full rated thermal capacity for a wide range of refrigeration requirements and refrigerants. Standard design features meet today’s environmental requirements by minimizing refrigerant charge and energy consumption. They are characterised by low installation costs and enable reliable year-round operation with low maintenance requirements.

operating principle

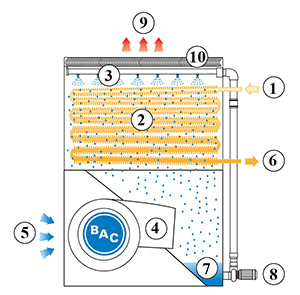

The CXVE combines an evaporative condenser tube bundle with an integrated packed packing for cooling the circulating spray water.

The steam (1) flows through the condenser coil (2), which is moistened by a spray system (3). Parallel to the water spray flow, an axial fan (4) sucks in air (5) via the tube bundles. The evaporative cooling converts the vapour into liquid (6). The spray water falls onto a packing (7), where it is cooled before falling into the water basin (8) or the inclined tub. The spray water pump (9) returns the cooled water to the top of the unit. The warm saturated air (10) leaves the tower through the droplet separators (11), which remove the water droplets from the air.

Typical applications are:

- Industrial cooling applications in noise sensitive environments

- Low energy consumption

Main advantages of the CXVE:

- Highly efficient

- Low maintenance and easy inspection

- Excellent hygiene control

Main advantages in detail

Due to their lower condensing temperatures, evaporative cooling units minimize the energy consumption of the overall system and are considerably more efficient than conventional air-cooled and water-cooled condensing systems. This saves costs, protects raw materials and the environment. The CXV delivers heat dissipation with the lowest possible energy consumption through Evaporative Cooling PLUS, an excellent combined heat transfer system with patented multi-flow design, low kW axial fans that use half the energy of comparable radial fans, and BACross II packings that ensure optimum efficiency of the unit through unprecedented water/air contact with minimal air-side pressure drop. In addition, it has a highly efficient motor system with several fans: Since each fan has its own motor and drive assembly, it is possible to regulate power as required in small steps.

Hinged doors allow easy access to the interior of the unit. All CXVE models come standard with an internal catwalk.

In the spacious interior, the cold water basin, the droplet separators, the fan drive system and the condenser tube bundle are easily accessible. A basin must be drained for internal inspection. The parallel flow of air and water spray over the tube bundle allows inspection and access to the top of the tube bundle during operation. It is easy to reach via the droplet separators which can be removed from the outside and inside. Since the patented multi-flow technology reduces evaporation directly from the tube bundle, the risk of deposits is significantly reduced. Inspection of the water distribution system (spray arms and nozzles) outside the unit is also possible during operation. The patented BACros II fillers are also easy to inspect from the inside or outside using removable, combined air intake protective elements. Since the individual packing steel sheets are telescopically supported, the packing does not have to be dismantled. The inclined position of the filling material and the slope of the basins also ensure a continuous self-cleaning process by washing out foreign bodies and impurities. An optional cleaning opening facilitates the removal of silt and sludge from the cooling tower basin. The CXVE has anti-turbulence structures with a removable suction strainer. The fans can be tested from inside and outside. Fresh water and overflow are also easily accessible for inspection or cleaning.

Da die CXVE-Türme infach zu reinigen und zu inspizieren sind, verringern sich Hygienerisiken aufgrund von Bakterien, wie etwa Legionellen, oder Biofilm im Inneren. Die patentierten Bacross II-Füllkörper-Stahlbleche verringern Fouling und sind teleskopisch gestützt, wodurch eine komplette Inspektion und Reinigung des Füllkörpers ohne Zerlegen möglich wrd. Die kombinierten Lufteintritts-Schutzelemente blockieren das Sonnenlicht, verhindern so biologisches Wachstum im Turm, filtern die Luft und sorgen dafür, dass kein Wasser nach außen spritzt. Dank der hocheffizienten Tropfenabscheider, können keine Tröpfchen in die Luft gelangen. Ihre Leistung ist von Eurovent zertifiziert und getestet. Eine optionale Reinigungsöffnung erleichtert die Entfernung von Schluff und Schlamm aus dem Kühlturmbecken. Außerdem ist optional eine Wannenabsaugung erhältlich, die das Ansammeln von Sedimenten im Kaltwasserbecken verhütet.

The patented heat transfer system requires less tube bundle surface area. Multi-flow technology provides maximum performance with the lowest refrigerant charge compared to other units in this performance class. The low refrigerant charge reduces installation costs and can help meet refrigerant charge thresholds. As a result, the operating costs of the overall system are reduced.

The excellent multi-flow heat transfer system via heat exchanger coil and packing is particularly suitable for applications with temperature fine tuning and thermal challenges. Motor system and multiple fans ensure independent operation of fan motor and drive assembly per fan. They can also be used for additional power regulation or as a standby fan in the event of a fan failure. The use of various corrosion-resistant materials, such as the unique Baltibond hybrid coating, guarantees a long service life. The one-sided air inlet and outlet is suitable for most installation conditions.

CXVE units contain low-noise axial fans for minimum ambient noise. Whisper-quiet fans are available to further reduce the noise level. In addition, specially developed and dimensioned silencers are available to further reduce operating noise at the air intake. The one-sided air inlet and a quieter rear side of the tower allow the unit to be aligned in such a way as to shield noise-sensitive areas. The BACross II filler directs the water calmly and without splashing noises to the pool.

CXVE Evaporative Condensers are factory assembled and supplied in parts on larger models to reduce size and weight and allow easy assembly of parts on site with a smaller, less expensive crane.