Startseite > DFCV-AD Trillium Series

Trillium Series | DFCV-AD

DFCV-AD

The DFCV-AD is an axial counterflow cooler with adiabatic precooling according to the induced draft principle for a power range of 220 to 1,620 kW. The maximum liquid inlet temperature is 60°C. If the cooling requirement is at average ambient temperatures, dry air cooling becomes inefficient or impossible. The Trillium Series DFCV-AD provides reliable, safe and efficient liquid cooling to temperatures below ambient, while reducing water consumption. It offers the advantages of evaporative cooling in a safe dry cooling product.

operating principle

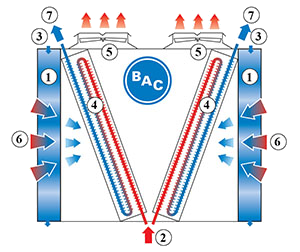

The DFCV-AD is a V-shaped dry cooler equipped with adiabatic precoolers (1) which cool the warm process liquid (2) by sensitive heat transfer. Water flows (3) evenly over the evaporative cooling pads located in front of the dry finned coil (4). At the same time, axial fans (5) suck air (6) through the pads, evaporating part of the water and cooling the saturated air. This increases the cooling capacity of the incoming air for cooling the process liquid (7) in the tube bundle.

Typical applications are:

- Small to medium climate and industrial applications

- Sites with limited water and space availability

- Commercial applications with high temperatures

Main advantages of the DFCV-AD:

- High thermal performance

- Water saving

- High operational reliability due to excellent hygiene control

Main advantages in detail

The DFCV-AD is a V-type dry cooler with special adiabatic air precoolers that significantly increase its performance, reduce its size and allow the process liquid to be cooled well below ambient temperature. The adiabatic pre-cooling, consisting of highly efficient evaporation pads in a stainless steel frame, is only activated when required (high outside temperature). Then water flows evenly over the evaporation pads. When the air flows through the precooler, some of the water evaporates, humidifies the air and cools it to temperatures 2 – 3 °C above the wet bulb temperature. The adiabatic pre-cooling increases the performance of the cooler by up to 40% compared to dry coolers.

The DFCV-AD from the Trillium series is supplied with a control system that activates adiabatic precooling in two stages as required, thus limiting water consumption to very short periods of time. Compared to traditional evaporative cooling without integrated hybrid technology and controls, this cooler saves over 85% water.

While some of the water that flows over the evaporation pads evaporates to cool the air, the excess water is used to flush out foreign bodies and minerals that remain behind the precooler after evaporation. The adiabatic pre-cooling of TrilliumSeries coolers is a continuous flow system in which there is neither recirculation nor stagnant water. This avoids the risk of microbiological contamination and bacterial proliferation. After each adiabatic pre-cooling cycle, the drain valves open automatically, completely draining and drying the entire water distribution pipe system. The design of the evaporation passes guarantees that neither droplets nor aerosols are produced during adiabatic pre-cooling. Both lead to a sustainable middling of the legionella risk. The DFCV-AD cools the incoming air without water transfer to the dry finned tube bundle, i.e. there is no droplet rupture which could lead to deposits.

Since the Trillium refrigeration units do not require any water pumps, they consume considerably less energy than conventional evaporative coolers. The low process temperatures reduce the energy consumption of the entire system. As an option, the DFCV-AD is also available with an EC motor and improved pre-cooling performance, which significantly minimizes operating noise and reduces energy consumption by 25%.

Unlike dry coolers equipped with spray systems, this Trillium Series cooler provides stable and predictable thermal performance without the need for high-pressure pumps and water treatment. The evaporation pads can be removed during colder seasons. However, adiabatic precooling can also be used year-round to improve energy efficiency and act as a filter to protect the dry tube bundle from airborne contaminants.