Startseite > S1500E

Open Cooler | S1500E

Open Cooling Systems | S1500E

The 1500E Series axial cross-flow cooling towers minimize operating, installation and maintenance costs for new installations and replacement cooling tower projects. The S1500E Series delivers full thermal rating for flow rates from 8 – 215 l/s at a maximum water inlet temperature of 55°C (standard packing) to 60°C (alternative packing) at 40% more power. The water is distributed by gravity and can be regulated by means of weir dams in the hot water basin. 1500 Series cooling towers minimise the operating, installation and maintenance costs associated with new installations and replacement cooling tower projects. Standard design features minimize the costs associated with enclosures, substructure requirements, power supply, piping system and installation.

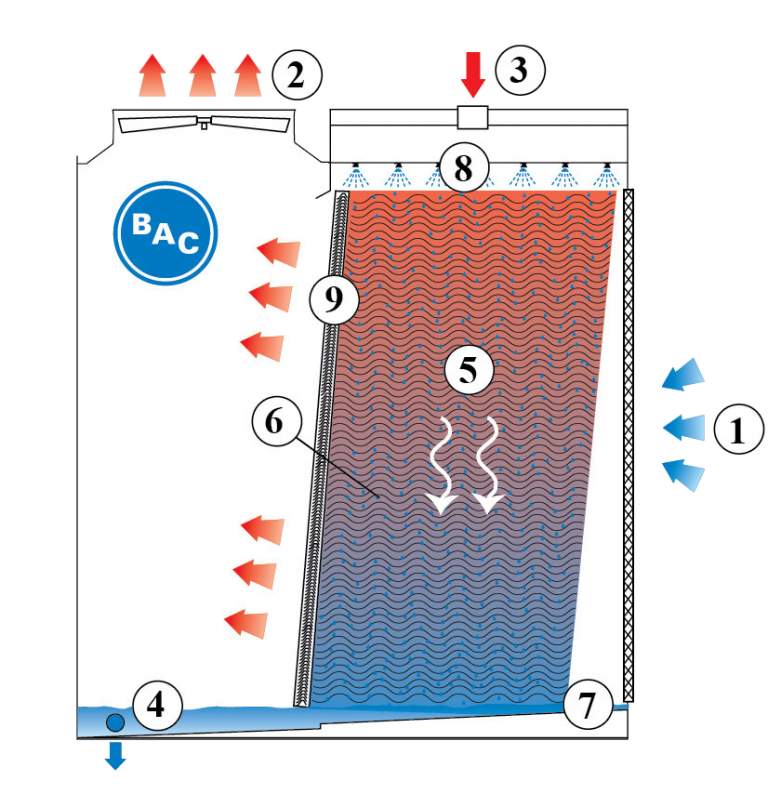

Operating principle

Hot process water (3) from the top of the cooling tower into the water distribution (8) where it is distributed over the packing or heat transfer medium (6). At the same time, the axial fans located at the top of the unit blow air (1) from the sides of the unit over the packing. Combined air inlet protection elements protect the tower from foreign bodies being sucked into the unit. When the hot process water meets the cold air, the latter is heated and part of the process water evaporates, removing heat from the rest of the water. The trough (7) or inclined basin collects the cooled water, which then returns to the heat source of the process (4). The warm saturated air (2) first passes the droplet separators (9), which remove the water droplets from the air, and then leaves the tower at the top.

Typical applications are:

- Medium climate and industrial applications

- Replacement of counterflow and crossflow devices

- Tight installation conditions

- Installations requiring a single air inlet

key benefits

- Extremely low noise level

- Unprecedented energy savings, payback period of less than 2 years

- Low maintenance and easy inspection, 25% reduction in annual maintenance costs

Main advantages in detail

The noise level corresponds to that of radial fans with silencers. We offer a selection of different low-noise axial fans and whisper-quiet fans for minimum ambient noise. The BACross filler directs the water calmly and without splashing noises to the pool. The one-sided air inlet and a quieter rear side of the tower allow optimal alignment for noise-sensitive areas. A further reduction in operating noise is achieved by specially developed, dimensioned and tested silencers at the air intake. In addition, we offer the XES1500E series with smaller motors for extremely quiet operation.

Evaporative cooling units minimize the energy consumption of the entire system due to their low operating temperatures. This series uses highly efficient axial fans with a low kW output. The water distribution by gravity and the lower pump head also saves energy for the pumps, as does the possibility of partially closing the hot water basin during periods of reduced load due to weir dams. To further optimize cooling tower efficiency, the packing is factory designed for maximum air/water contact time with low air pressure losses. In addition, there are highly efficient fan motors. Using the XES1500E series with smaller motors can further reduce power consumption with the same cooling capacity. A motor system drives several fans with independent drive groups. This allows the performance to be regulated step by step according to demand. If one fan fails, the other fan(s) will continue to operate.

A large hinged door and a spacious maintenance channel provide safe and convenient access for inspection and maintenance. Optionally, an internal catwalk can be integrated. No basin needs to be drained to inspect the inside of the device or the packing package. The inspection of the water distribution (nozzles and hot water basins) is possible from the outside during operation. The inclined position of the packing and the slope of the cold water basin facilitate the rinsing out of dirt and foreign bodies from critical areas. An optional cleaning opening helps remove sludge from the cooling tower basin. The core of the BACross packing can be inspected and cleaned sheet by sheet without disassembly. Optional telescopic packing carriers simplify blade replacement. The packing contains Eurovent tested and certified droplet separators. In addition, the S1500E has anti-turbulence structures with a removable suction strainer. The fans are easily accessible from inside and outside. An optional engine removal davit is available for easy engine replacement.

The units are suitable for direct mounting on existing steel girders of many cooling towers (both cross-flow and counter-flow). The fan motors can be supplied according to the existing wiring. These units fit into most existing enclosures due to the one air inlet design with little or no modification. The small fan motors and the low spraying pressure make it possible to reuse the existing control cabinet. S1500E cooling towers are factory assembled and supplied in one or two parts to reduce overall size and weight and allow easy on-site assembly with a smaller crane.

A proper hygiene inspection can be carried out without switching off the device. Hygiene risks due to bacteria (Legionella) or biofilm inside are significantly reduced due to the simple cleaning and inspection. The BACross design reduces possible fouling in the packing, which can be cleaned sheet by sheet without dismantling. Combined air inlet protection elements block the sunlight to prevent biological growth in the tower, filter the air and ensure that no water splashes out. Optional covers on the water distribution tray prevent foreign bodies from accumulating in the unit. The inclined position of the filling material and the gradient in the cold water basin ensure continuous self-cleaning by rinsing out dirt and frenzy. An optional tub suction system additionally prevents the accumulation of sediments in the cold water basin. An optional cleaning opening helps remove sludge from the cooling tower basin. In addition, Eurovent tested and certified droplet separators are integrated in the filling material.

As an inspection during operation is possible, an optimal condition of the device can always be guaranteed. Corrosion-resistant materials, such as the unique Baltibond hybrid coating, guarantee a long service life. The motor system, which drives several fans with independent drive groups, prevents total failures, because if one fan fails, the other fan(s) continues to work. In addition, there is proven winter operation without freezing.