Startseite > FXV-E

Evaporative Condenser | PFE

FXV-E

The PFE is an axial counterflow cooling tower based on the induced draught principle for a power range up to 1,270 kW and a maximum liquid inlet temperature of 82°C. The PFE is a cooling tower with a high suction capacity. The water is distributed under pressure. PFE evaporative coolers with closed cooling circuit reduce the energy consumption of the entire system due to the low operating temperatures. The possibility of dry operation at low outside temperatures not only reduces energy consumption even further, but also reduces vapour formation.

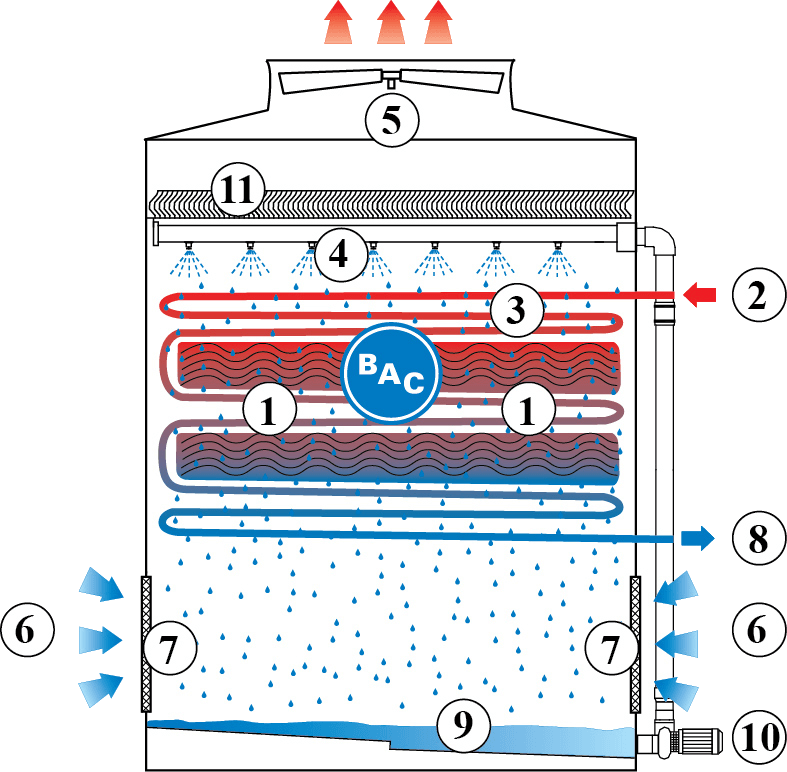

Operating principle

Warm process liquid (1) flows through a heat exchanger coil (2), which is sprayed with water by a spray system (3) at the top of the cooling tower. At the same time, the axial fan (4) draws ambient air upwards through the tower (5). During operation, heat is first transferred to the water and then to the atmosphere, while part of the water evaporates. The cooled process liquid then leaves the unit (6). The tub (7) or the inclined basin collects the remaining water. The spray water pump (8) lets the water flow back to the spray system. The warm saturated air (9) leaves the tower via the droplet separators (10), which remove the water droplets from the air.

Typical applications of the PFE are:

- Medium to large climate and commercial applications

- Dry operation in winter

key benefits

- Low energy consumption

- Low noise

- Easy to maintain

Main advantages in detail

Evaporative cooling towers such as the PFE reduce the energy consumption of the entire system due to their low operating temperatures. The axial fans of the PFE require only half the energy of comparable radial fan units. PFE cooling towers also feature highly efficient fan motors and tube bundles, further reducing energy consumption.

The PFE is supplied as standard with low-noise axial fans. If the operating noise is to be further reduced, we also offer whisper-quiet fans. In addition, the noise level can be further reduced with the aid of specially developed and dimensioned silencers for the air intake. The use of water silencers, which are always supplied with whisper-quiet fans, reduces operating noise to the level of cross-flow cooling towers.

PFE units with a closed cooling circuit are easier to maintain than other counterflow cooling towers based on the induced draft principle: The individual arms of the BranchLok water distribution system can be easily removed and cleaned. The combined air inlet protection elements can be removed without tools. The cold water pool is then fully accessible. An optional cleaning opening facilitates the removal of sludge from the cooling tower basin. The PFE has a removable suction strainer with anti-turbulence components. The motor adjustment elements are accessible from the outside and have an integrated spanner for easy motor alignment and belt tensioning. A sliding door provides access to the fan system.

At times of lower load, the spray system can be bled off and the PFE can be used in dry operation. For longer dry operating times, we recommend equipping the unit with a finned coil on the discharge side. This can also reduce the formation of vapours in wet operation and in some cases completely avoid them as well as significantly reduce water consumption.

Since the PFE has a closed cooling circuit, no impurities from the air can penetrate and lead to fouling in the system. The simple cleaning and inspection of the PFE towers reduces hygiene risks due to bacteria (e.g. Legionella) or biofilm inside. Due to the incline of the cold water basin and the inclined position of the filling material, dirt and foreign bodies are continuously flushed out. The combined air inlet protection elements block the sunlight, thus preventing biological growth in the tower, filtering the air and ensuring that no water splashes to the outside.

The leak-free InterLok system allows quick installation of the PFE cooling tower on site. The basin can be installed in the upper part without sealing tape. The PFE only requires a small footprint and is therefore perfectly suited for enclosed spaces. Delivery in containers is often possible.