Startseite > SP Spartium Cooler

SP Spartium Cooler

SP Spartium Cooler from the Trillium series: closed cooling circuit with adiabatic precooling

![Spartiumcooler_4[1]](https://ertgmbh.de/wp-content/uploads/elementor/thumbs/Spartiumcooler_41-nxxzt5lfje3qutxb0iqqh1p1jy74tdjptrljhvkdrs.jpg)

![Spartiumcooler_1[1]](https://ertgmbh.de/wp-content/uploads/elementor/thumbs/Spartiumcooler_11-nxxzt5lfje3qutxb0iqqh1p1jy74tdjptrljhvkdrs.jpg)

The SP SpartiumCooler from the Trillium series is an axial counterflow cooler with adiabatic precooling according to the induced draft principle for a power range from 340 to 1,560 kW with a maximum liquid inlet temperature of 60 °C. The SP SpartiumCooler is an axial counterflow cooler with adiabatic precooling according to the induced draft principle. The SpartiumCooler is designed to achieve maximum adiabatic pre-cooling of the air while eliminating the risk of uncontrolled growth of algae, mucus and other microorganisms such as Legionella. The SpartiumCooler comes standard with an electrical console that supports all common communication protocols.

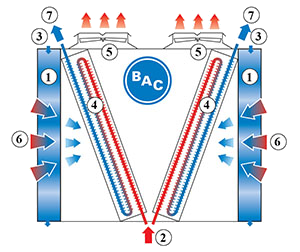

Operating principle

The SP SpartiumCooler is a dry cooler equipped with adiabatic precoolers (1) that cool the hot process liquid (2) by sensitive heat transfer. Water flows (3) evenly over the evaporative cooling pads located in front of the dry finned coil (4). At the same time, axial fans (5) suck air (6) through the pads, evaporating part of the water and cooling the saturated air. This increases the cooling capacity of the incoming air for cooling the process liquid (7) in the tube bundle.

Typical applications are:

- Small to medium climate and industrial applications

- Sites with limited water and space availability

- Commercial applications with high temperatures

Main advantages of the SP SpartiumCooler:

- Cost-effective delivery and installation

- Water saving

- Excellent hygiene control

Main advantages in detail

SP SpartiumCooler from the Trillium series fit on normal trucks. Your pre-coolers are already factory assembled. Only small cranes are needed for their installation. This minimizes delivery and installation costs and sustainably reduces the logistical effort.

Since adiabatic pre-cooling is only necessary during the warm season, SP SpartiumCooler achieve annual water savings of over 80% compared to conventional evaporative coolers.

The SP SpartiumCooler has a water flow system that excludes stagnant water, as the pre-cooling water is discharged directly from the pads into the waste water via an outlet. The excess water is used to rinse out impurities from the evaporation pads. Therefore neither a circulation nor a water treatment is necessary. At the same time, both the formation of aerosols is excluded, so that even in the unlikely event that Legionella growth takes place, they cannot enter the air. In addition, the transfer of water to the dry tube bundle is excluded, so that no evaporation deposits can occur here.

The evaporation pads cool the air down practically to the wet bulb temperature. This leads to a performance increase of up to 40% compared to conventional dry cooling. Since no water pumps are required, the energy consumption of the SP SpartiumCooler is lower than that of a conventional evaporative cooler. The low process temperatures lead to low energy consumption throughout the system.